Double Y axis dispensing machine with high dispensing flexib

作者:點(diǎn)膠機(jī)內(nèi)存卡 日期:2018-09-21 18:20 瀏覽:

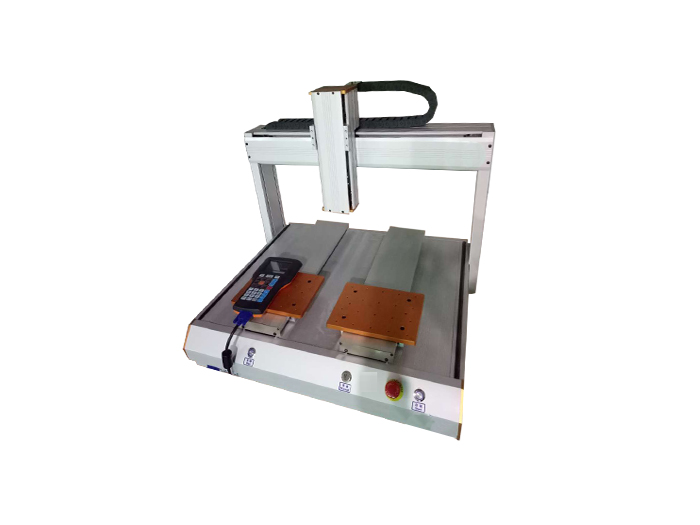

Introduction of desktop double Y shaft dispensing machine

Desktop type double Y axis dispensing machine is desktop type. In this desktop dispensing machine workbench, two automatic platforms are assembled. It has the advantages of improving the flexibility of dispensing and facilitating the replacement of products. There are many kinds of glue for desktop double Y-axis dispensing machine, such as optical glue, UV glue, hot-melt glue, anaerobic glue and so on. Because of the particularity of these glues, we can know the glue properties before using them to do a good job of preparation, which can ensure the quality of tempered film dispensing production.

Desktop dual Y axis dispensing machine works with high flexibility.

Desktop double Y-axis dispensing machine is equipped with two automatic platforms. In the application of tempered film dispensing links, the application of Z-axis and X-axis in desktop dispensing machine can effectively improve the flexibility of work, which has a great relationship with the production and quality of tempered film dispensing. If the tabletop dispensing machine is not equipped with a manipulator, the need for manual replacement of the tempered film to complete the optical dispensing work, then loading the double Y-axis can also facilitate the replacement of products.

Application of toughened film dispensing to desktop dispenser

It is difficult to meet the demand of production by using ordinary desktop dispensing machine. This desktop double Y-axis dispensing machine has advantages in positioning accuracy and glue output control besides high flexibility. It is used in the optical glue links of toughened film dispensing. Using this desktop dispenser can effectively improve production quality and efficiency.

The desktop dual Y-axis dispensing machine with high flexibility can be used in a wide range of industries, but the quality of the glue used and the demand for dispensing need to be considered before use to adjust the appropriate production parameters.

Desktop double Y-axis dispensing machine is equipped with two automatic platforms. In the application of tempered film dispensing links, the application of Z-axis and X-axis in desktop dispensing machine can effectively improve the flexibility of work, which has a great relationship with the production and quality of tempered film dispensing. If the tabletop dispensing machine is not equipped with a manipulator, the need for manual replacement of the tempered film to complete the optical dispensing work, then loading the double Y-axis can also facilitate the replacement of products.

Desktop double Y-axis dispensing machine is equipped with two automatic platforms. In the application of tempered film dispensing links, the application of Z-axis and X-axis in desktop dispensing machine can effectively improve the flexibility of work, which has a great relationship with the production and quality of tempered film dispensing. If the tabletop dispensing machine is not equipped with a manipulator, the need for manual replacement of the tempered film to complete the optical dispensing work, then loading the double Y-axis can also facilitate the replacement of products.